Introduction

Valves are critical components in piping systems, responsible for controlling the flow of fluids and gases in industrial, commercial, and domestic settings. Among the various materials used in valve construction, cast iron and cast steel are two of the most common. Although they may appear similar, these materials differ significantly in composition, mechanical properties, and suitability for various applications. Choosing between cast iron and cast steel valves requires a clear understanding of these differences to ensure long-term reliability, safety, and cost-efficiency.

Material Composition and Metallurgy

Cast iron is an iron-carbon alloy with a carbon content typically above 2%. It contains a significant amount of graphite in the form of flakes (gray cast iron) or nodules (ductile cast iron), which greatly influences its properties. It may also contain silicon, manganese, and trace elements. Cast iron’s high carbon content makes it relatively brittle but easy to cast into complex shapes.

Cast steel, on the other hand, is an iron-carbon alloy with a carbon content usually below 2%. It is essentially carbon steel or alloy steel that has been cast into a desired shape. The lower carbon content and absence of graphite provide better ductility, toughness, and weldability compared to cast iron. Cast steel may also be alloyed with chromium, molybdenum, or nickel to improve its strength and corrosion resistance.

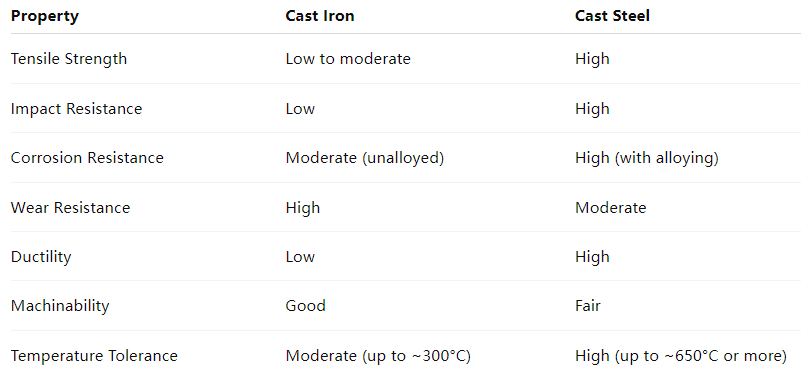

Mechanical Properties

When it comes to mechanical performance, cast steel outperforms cast iron in almost every aspect. Cast steel exhibits higher tensile strength, impact resistance, and toughness. These properties make it well-suited for high-pressure and high-temperature environments, as well as applications subject to mechanical shock and vibration.

Cast iron, due to its graphite content, has excellent compressive strength and good machinability, but it is brittle and prone to cracking under tensile stress or impact. Its vibration damping capability, however, is superior, which is beneficial in certain static applications.

Applications and Use Cases

Cast iron valves are commonly used in:

Water and wastewater treatment systems

Municipal piping networks

HVAC (Heating, Ventilation, and Air Conditioning) systems

Fire protection piping

General-purpose low-pressure applications

Cast steel valves are better suited for:

Oil and gas industries

Power generation plants

High-pressure steam and chemical pipelines

Petrochemical refineries

Mining and process industries

Due to their strength and toughness, cast steel valves are often found in critical applications where valve failure could result in severe consequences, such as explosions, leaks, or costly downtime.

Cost Considerations

Cost is often a deciding factor in valve selection. Cast iron valves are generally more economical, both in terms of raw material and manufacturing costs. They are easier to cast, machine, and mass-produce. For low-pressure, non-critical applications, cast iron is often the preferred choice due to its affordability.

Cast steel valves are more expensive due to the higher cost of steel, alloying materials, and more complex heat treatment processes. However, the higher upfront cost is often justified by their longer lifespan and superior performance in demanding conditions.

Corrosion Resistance and Maintenance

While cast iron is prone to corrosion if not coated or protected, certain grades like ductile iron can offer improved resistance. Coatings such as epoxy, enamel, or galvanization are often applied to enhance durability.

Cast steel, especially when alloyed with chromium (such as stainless steel), offers much better corrosion resistance. This makes cast steel valves more suitable for corrosive environments, such as chemical plants or marine applications. Maintenance requirements for cast steel valves are generally lower, but they must still be inspected regularly for wear, especially in abrasive or corrosive systems.

Standards and Grades

Both cast iron and cast steel valves are manufactured according to stringent international standards, such as:

ASTM A126, A48, A536 – for cast iron and ductile iron valves

ASTM A216, A217, A351 – for cast steel and stainless steel valves

These standards define the chemical composition, mechanical properties, and testing requirements for valves, ensuring consistency and safety across industries.

中文简体

中文简体 English

English русский

русский